Screen Printing vs. Sublimation: Which is Best for Custom Gym Wear?

2025-07-22

2025-07-22

Sansansun

Sansansun

Custom gym wear continues to define brands and sports teams. Sportswear manufacturers know that every choice—from materials to decoration method—affects how gym clothes look, feel, and perform. The two most popular methods, screen printing and sublimation, each bring unique strengths and challenges. Material, durability, design freedom, and order size all influence which process rises to the top for custom pieces.

Basics of Screen Printing and Sublimation for Gym Wear

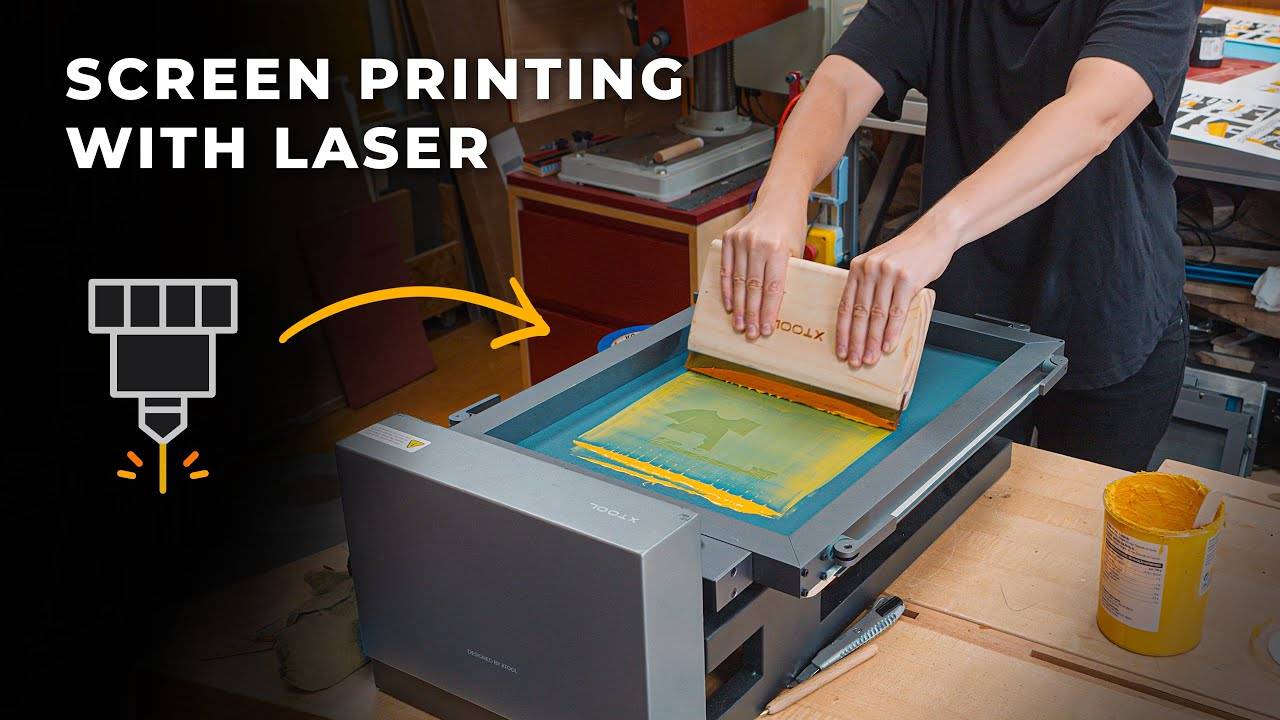

Screen printing uses a mesh stencil to push ink onto fabric. Each color in the design gets its own screen, making multi-color designs more complex. The ink sits on top of the material, creating bold, opaque graphics. It works on almost every fabric, including blends, cotton, and performance synthetics.

Sublimation, on the other hand, relies on heat and pressure to turn solid dye into a gas. This dye bonds with polyester fibers, so the print becomes part of the fabric itself. The result? Detailed, vibrant patterns that cover the entire garment without adding extra weight. Sportswear manufacturers frequently adopt sublimation for all-over designs and photo-quality graphics, especially when lightweight polyester is in play.

Durability and Performance: What Athletes Need

How long does the print last under daily gym demand? Sublimated prints won't crack, peel, or fade as they live within the fabric. Even after dozens of washes, colors stay true, and prints remain smooth. Sublimation also keeps polyester’s stretch, breathability, and moisture-wicking properties intact—key for activewear.

Screen printing offers toughness, especially when using quality inks on premium material. But over time, thick ink layers might crack or fade, especially if the piece stretches often or goes through harsh washes. Still, screen printing shines for simple logos or bold statements, especially if your gym wear isn’t put through the wringer every day.

Design Limitations and Customization Options

Design flexibility sets these methods apart. Sublimation is the go-to for full-cover patterns, gradients, or photo-realistic graphics. The dye embeds directly, so you aren’t limited to a certain number of colors or design shapes. Sportswear manufacturers often recommend sublimation for teams wanting vibrant, complex gear.

Screen printing handles bold graphics, text, and crisp logos best. Each color adds cost and setup, so it fits designs with limited shades. While you can add special effects (like puff prints), detailed artwork or all-over prints are better suited for sublimation. For classic gym tank branding and single-color logos, screen printing gets the job done fast and affordably.

Cost Considerations and Best Use Cases

For small batches or highly personalized gear, sublimation is cost-efficient. There’s almost no setup, and you can mix and match designs with no extra charges. As orders scale up, though, the price per item doesn’t drop as much.

Screen printing requires more setup, but each additional shirt drops in cost for large runs. If you need hundreds of shirts for a gym event or team season, screen printing quickly becomes the economical winner.

Best Use Cases:

Sublimation: Unique team kits, small orders, detailed or full-coverage designs, premium high-performance wear.

Screen Printing: Bulk orders, basic branding, single or two-color graphics, fundraising shirts.

Conclusion

Sportswear manufacturers use both screen printing and sublimation to meet a wide range of needs. Choosing the right process depends on your design vision, budget, and performance expectations. For vivid, durable prints on polyester, especially when every piece needs a unique twist, sublimation leads the way. For classic logos, large team orders, or straightforward branding, screen printing keeps things simple and cost-effective. Whether outfitting a team or creating standout gym apparel, match your print method to your goals for the best result.

Inquire(

Inquire(

HOME

HOME How to Start a Profitable Custom Activewear Business in 5 Steps

How to Start a Profitable Custom Activewear Business in 5 Steps  You May Also Like

You May Also Like

Tel

Tel

WhatsApp

WhatsApp

Email

Email

Address

Address