How to Choose the Right OEM Clothing Manufacturer

2025-05-15

2025-05-15

Sansansun

Sansansun

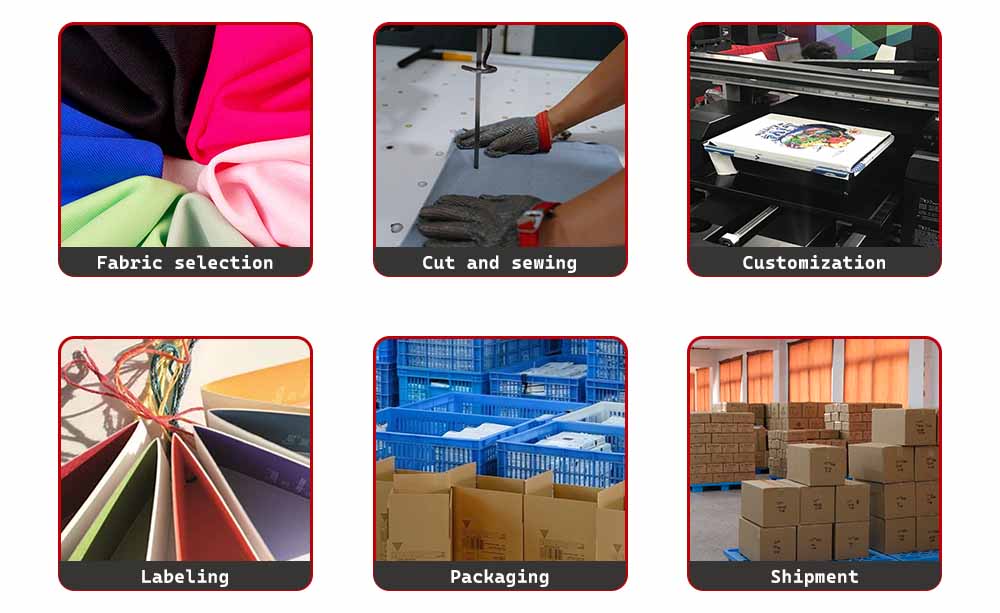

In the vast territory of the fashion industry, the OEM (original equipment manufacturer) production model plays a pivotal role. Simply put, OEM means that manufacturers handle the production of clothing according to the design concepts and specifications given by the brand. The brand firmly controls the design and marketing links, while the manufacturer is fully responsible, providing one-stop service from the careful procurement of fabrics to the orderly development of mass production, to the final packaging link.

1. Disassembly of the whole process of OEM clothing manufacturing

Design and pattern making: This step is the starting point of the entire production process. According to the design drawings or specific requirements provided by the customer, the clothing is accurately designed and patterned, and paper samples and templates are produced to lay a solid foundation for subsequent production links.

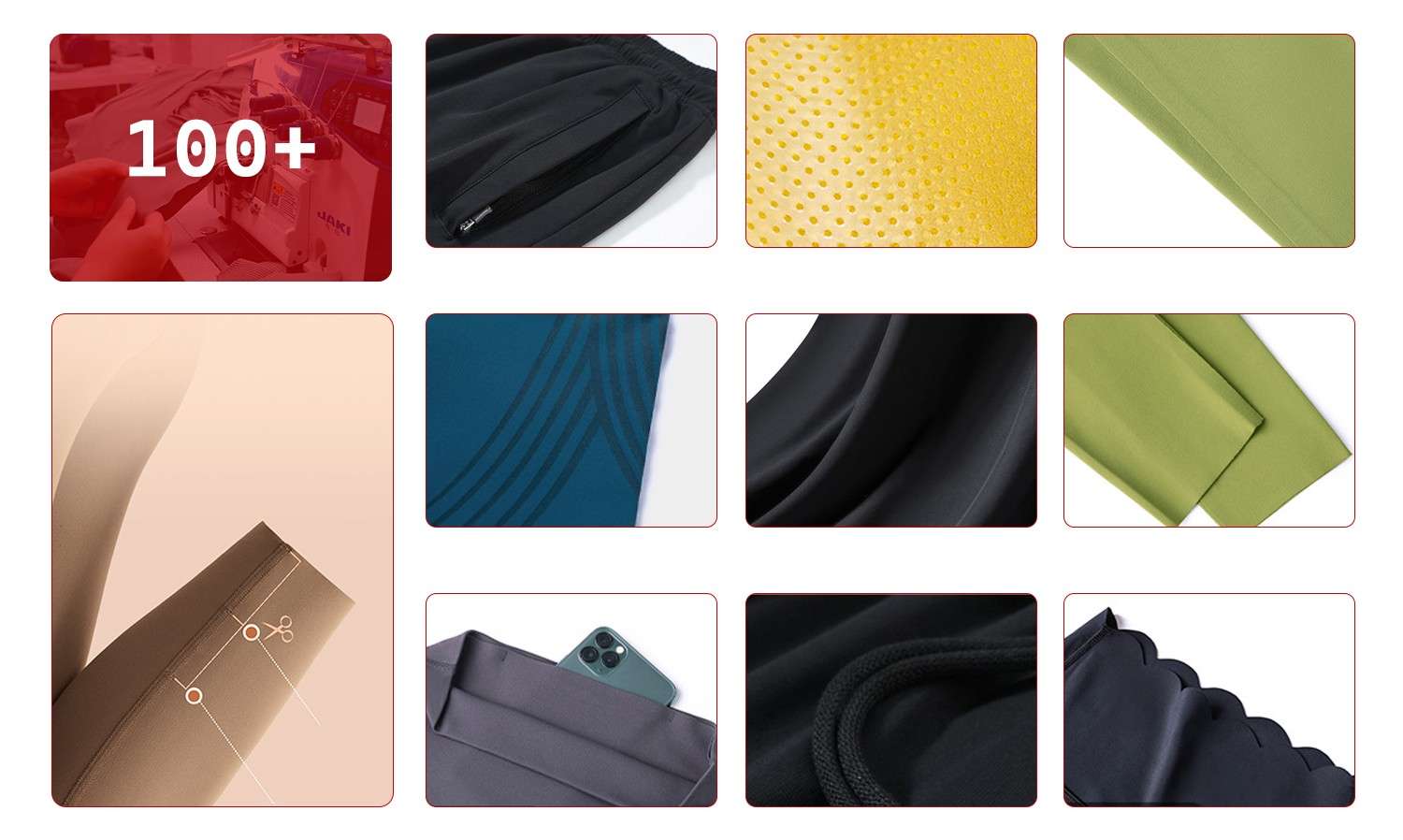

Surface and auxiliary material procurement: Refer to the design requirements to start the procurement of fabrics, linings and various auxiliary materials. In the procurement process, strictly control the quality to ensure that the purchased surface and auxiliary materials are of high quality, and the quantity must meet the production needs to avoid production interruptions due to shortage of raw materials.

Inspection of fabrics and accessories: Comprehensive and detailed inspection of purchased fabrics and accessories, including whether the appearance is intact and whether the internal quality meets the standards, resolutely prevent unqualified materials from flowing into the next production link, and ensure product quality from the source.

Cutting process: Before cutting, carefully check the information of the fabrics and accessories, including style, size, etc., and check and mark the defects on the fabrics and accessories. Then, precise cutting is carried out according to the sample and production requirements to ensure that the quality of the cut pieces meets the standards of subsequent production.

Sewing process: The sewing workers strictly follow the process sheet and sample requirements, select suitable sewing equipment and high-quality wire for sewing operations, and ensure the sewing quality in all aspects, including the uniformity of the stitches, the firmness of the stitches, and other details.

Ironing operation: Ironing workers use ironing equipment in accordance with the established process requirements to iron fabrics, cut pieces and ready-made clothes, so that the clothes can achieve a flat and crisp visual effect and enhance the overall quality of the clothes.

Special process treatment: In accordance with the personalized requirements of customers, a series of special process treatments such as printing and embroidery, washing, sanding, coating, etc. are carried out to add unique style and charm to the clothing.

Buttonhole and buttoning process: According to the established standard process, buttonholes, buttoning, and zipper installation are carried out to ensure that all kinds of accessories are firmly installed and accurately positioned for daily use by consumers.

Checking and repairing: For the sewn clothing, carefully check and repair work to check whether there are leaks, jumpers, uncleaned threads and other problems, and repair them in time. At the same time, trim off the excess threads to ensure the neatness and beauty of the product surface.

Quality control: This is a key link to ensure product quality, covering first-piece inspection, process inspection and finished product inspection. Through strict quality control at each stage of production, ensure that the quality of the products finally delivered to customers is excellent.

2. Analysis of the advantages of OEM clothing manufacturers

In-depth understanding of the advantages and limitations of OEM clothing manufacturing is of vital importance for clothing brands to make wise decisions when deciding to outsource production. The following are the main advantages and disadvantages of this field:

Cost advantage: OEM clothing manufacturers have excellent cost control with mature production facilities and a complete supply chain system. They can effectively reduce the production costs of clothing brands. This advantage is undoubtedly crucial for clothing brands with entrepreneurial dreams or smaller scales, helping them to gain a foothold in the fierce market competition.

Professional skills guarantee quality: OEM clothing manufacturers have been deeply involved in the field of clothing production for many years and have accumulated rich professional knowledge and practical experience. From the careful selection of fabrics, to the precise grasp of cutting, to the delicate operation of sewing and the final quality control link, they all demonstrate superb skills. Brands can make full use of the professional skills of manufacturers to ensure that the produced clothing meets high quality standards and industry specifications.

Help brand building focus: After choosing to outsource the production process to OEM manufacturers, clothing brands can get rid of the tedious production affairs and focus more energy and resources on their core strengths, such as design innovation, marketing promotion, and sales network expansion. This helps brands carefully build a strong and influential brand image and bring products to the market efficiently without worrying too much about the management of the production process.

3. How to accurately select the right OEM clothing manufacturer

Clarify product demand details: Brands need to clearly and detailedly sort out and outline their design style, fabric preferences, expected order quantity and customization needs. Only in this way can we accurately select partners that are highly consistent with our expectations from many manufacturers, and ensure that both parties can move towards the same goal in subsequent cooperation.

Comprehensively review the manufacturer's capabilities: In-depth investigation of the manufacturer's professional knowledge reserves, actual production capacity, raw material procurement channels, and quality control processes. It is imperative to ensure that these key factors are highly consistent with the brand's development strategy and product positioning, to provide strong guarantees for stable and high-quality product supply.

Comprehensively compare costs and cooperation terms: Collect quotation information from multiple manufacturers, and make detailed comparisons of their pricing strategies, minimum order quantity requirements, and payment terms. At the same time, it is also necessary to fully consider the additional services they provide, such as packaging, printing, embroidery, and logistics and distribution support. Under the premise of ensuring product quality, choose the most cost-effective manufacturer with the most favorable cooperation conditions.

Consider the level of communication and support services: Give priority to manufacturers who can keep communication channels unobstructed throughout the cooperation process, provide prompt feedback on production progress to the brand, respond quickly to various issues, and provide full customer service support. Good communication and service are key factors to ensure the smooth development of cooperation and the timely resolution of various emergencies.

On-site visits to factory facilities: If conditions permit, be sure to arrange time to visit the manufacturer's factory for an on-site inspection. Through on-site inspections, you can intuitively understand whether the manufacturer's production facilities are complete, whether the production technology is advanced, whether the work process is scientific and reasonable, and whether the overall management of the factory is standardized and orderly, to have a comprehensive and accurate judgment of the manufacturer's strength.

Sansansun Sports is a professional active wear manufacturers in china. We own two factories. One for sewing and cutting Another for seamless wear products. More than 50 sewing machines and more than 50 Santoni knitting machines. With 8 designers to do your custom design. We can offer low MOQ 150 pcs to do your private label active wear. With more than 20+ sales to do the professional service.Till now we have assist over 3000 clients to grow bigger and bigger. If your dream is to create an active or yoga wear brand in your own custom design or selecting from our ready to go items. Then we are here to make that your reality.

Inquire(

Inquire(

HOME

HOME Why has Lululemon's MVT series become a hit in men's sportswear?

Why has Lululemon's MVT series become a hit in men's sportswear?  You May Also Like

You May Also Like

Tel

Tel

WhatsApp

WhatsApp

Email

Email

Address

Address